air compressor для sale diesel

The Growing Market

3. Durability and Longevity Built with robust materials and engineering, the CFM 185 is designed to withstand demanding conditions, offering a longer lifespan and reliability for users.

The hammer itself can be operated using a pneumatic or hydraulic system, with hydraulic hammers being the preferred choice in most cases due to their consistent performance and reliability. The drill bit used is often designed specifically for marine environments, featuring reinforced materials and cutting edges optimized for hard substrates.

1. Offshore Oil and Gas Exploration In the oil and gas industry, submarine hammer drilling is crucial for the installation of subsea pipelines and wellheads. The ability to efficiently penetrate the seabed allows for the secure placement of infrastructure that can transport hydrocarbons from extraction points to processing facilities.

4. Renewable Energy Projects With the rise of offshore wind energy, submarine hammer drilling is increasingly used to install the foundations for wind turbines. The ability to achieve deep penetration in various seabed conditions makes this method invaluable in the renewable energy sector.

Increased efficiency and productivity

- Reduced downtime and maintenance costs

- Enhanced performance in challenging environments

Increased efficiency and productivity

- Reduced downtime and maintenance costs

- Enhanced performance in challenging environments

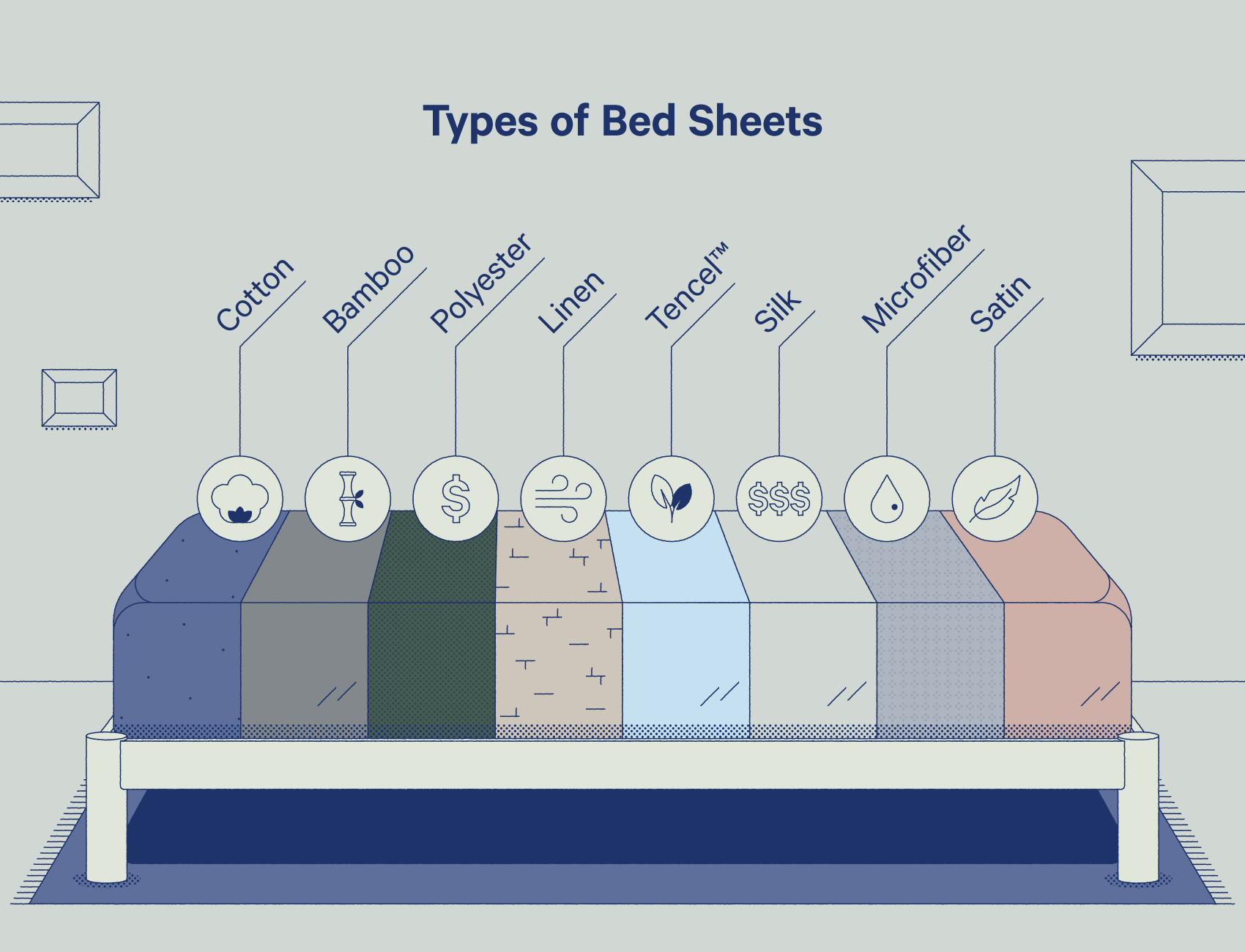

They are machine washable and tumble dryable, making it convenient to keep them clean and fresh They are machine washable and tumble dryable, making it convenient to keep them clean and fresh

They are machine washable and tumble dryable, making it convenient to keep them clean and fresh They are machine washable and tumble dryable, making it convenient to keep them clean and fresh

Available in a myriad of colors, patterns, and materials, these sheets can instantly uplift the look of a room Available in a myriad of colors, patterns, and materials, these sheets can instantly uplift the look of a room

Available in a myriad of colors, patterns, and materials, these sheets can instantly uplift the look of a room Available in a myriad of colors, patterns, and materials, these sheets can instantly uplift the look of a room With a traditional comforter, you may struggle to tuck in the excess material or adjust the corners to achieve a neat and tidy appearance With a traditional comforter, you may struggle to tuck in the excess material or adjust the corners to achieve a neat and tidy appearance

With a traditional comforter, you may struggle to tuck in the excess material or adjust the corners to achieve a neat and tidy appearance With a traditional comforter, you may struggle to tuck in the excess material or adjust the corners to achieve a neat and tidy appearance Bamboo is a highly renewable resource, and its cultivation requires minimal water and pesticides Bamboo is a highly renewable resource, and its cultivation requires minimal water and pesticides

Bamboo is a highly renewable resource, and its cultivation requires minimal water and pesticides Bamboo is a highly renewable resource, and its cultivation requires minimal water and pesticides It maintains its original form and color even after multiple washes, ensuring your sheets look as good as new for a longer period It maintains its original form and color even after multiple washes, ensuring your sheets look as good as new for a longer period

It maintains its original form and color even after multiple washes, ensuring your sheets look as good as new for a longer period It maintains its original form and color even after multiple washes, ensuring your sheets look as good as new for a longer period They have implemented eco-friendly practices throughout their production process, from sourcing raw materials to minimizing waste They have implemented eco-friendly practices throughout their production process, from sourcing raw materials to minimizing waste

They have implemented eco-friendly practices throughout their production process, from sourcing raw materials to minimizing waste They have implemented eco-friendly practices throughout their production process, from sourcing raw materials to minimizing waste